Ethyl chloroformate stands as a pivotal chemical intermediate in modern industry. This colorless liquid with a pungent odor serves as a building block for pharmaceuticals, agrochemicals, and organic synthesis. Its formula, ClCOOCH2CH3, enables reactions like esterification and carbonylation, making it indispensable.

Introduction

Ethyl chloroformate emerges from the reaction of ethanol and phosgene, positioning it as a versatile reagent. Industries rely on it for producing carbamates, carbonates, and peptides essential in drug manufacturing. Global production centers in Asia-Pacific, driven by chemical giants like BASF and Lanxess.

Demand stems from its role in synthesizing active pharmaceutical ingredients (APIs) and pesticides. Safety protocols dominate handling due to its toxicity and reactivity with water. Recent innovations focus on greener production methods to align with sustainability goals.

Review comprehensive data and projections in our Ethyl Chloroformate Market report. Download now:

https://www.databridgemarketresearch.com/reports/global-ethyl-chloroformate-market

Market Size

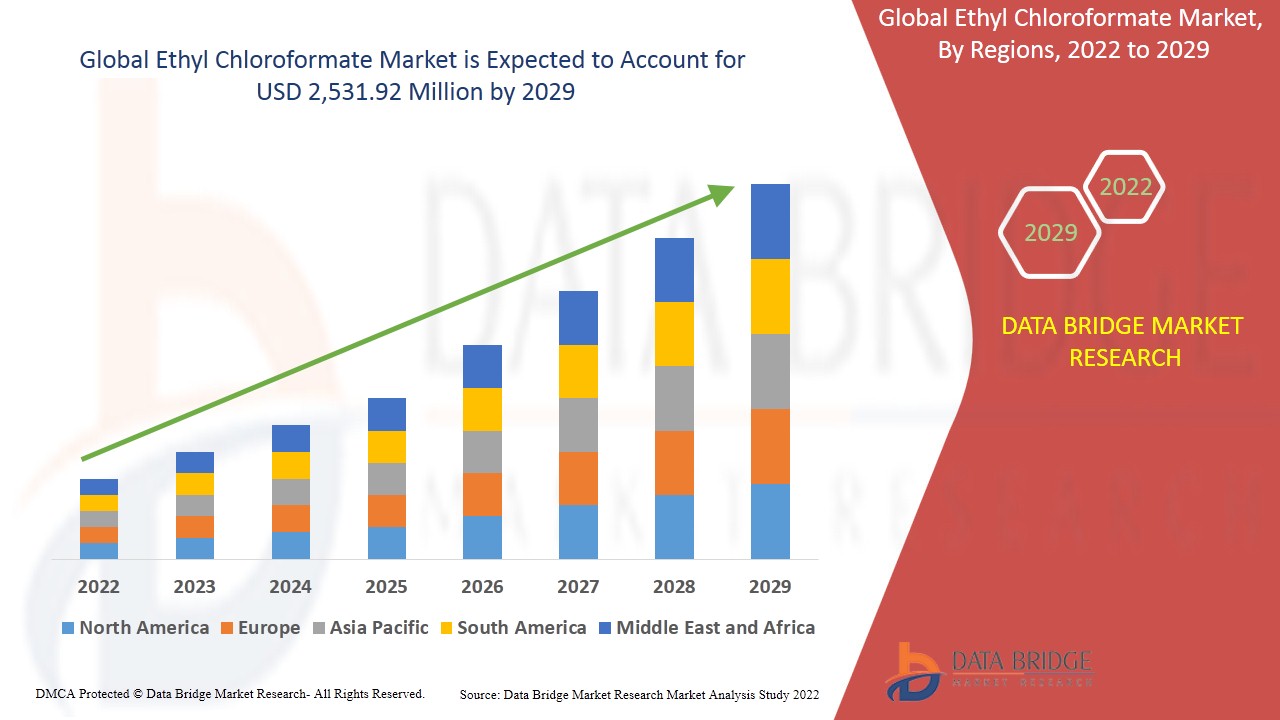

The ethyl chloroformate market reached USD 480.33 million in 2025. Projections indicate growth to USD 651.87 million by 2032 at a 4.4% CAGR. Alternative estimates peg 2023 value at USD 273 million, expanding to USD 402 million by 2032.

This expansion reflects rising pharmaceutical output and agrochemical needs. Asia-Pacific contributes the largest share, fueled by China and India’s manufacturing hubs. North America and Europe follow, emphasizing R&D in fine chemicals.

Market volume correlates with downstream applications, with liquid form dominating due to ease of handling. Investments in capacity expansion by key players bolster supply chains.

Market Share

Asia-Pacific commands over 40% market share, propelled by robust chemical industries in China and India. These nations lead in pharmaceutical and agrochemical production, consuming vast quantities of ethyl chloroformate.

Europe holds about 25%, with Germany and France excelling in high-purity variants for pharma. North America accounts for 20%, driven by innovative synthesis in the US. Emerging regions like Latin America and MEA grow steadily at higher CAGRs.

Key players like BASF, Lanxess, and Vande Mark control significant shares through integrated production. Chinese firms such as Hangzhou Dayang Chemical gain ground via cost efficiencies.

| Region | Market Share (%) | Key Drivers |

|---|---|---|

| Asia-Pacific | 40+ | Pharma/agro manufacturing |

| Europe | 25 | R&D focus |

| North America | 20 | Innovation |

| Others | 15 | Industrialization |

Market Opportunities

Pharmaceutical sector expansion offers prime opportunities, with rising API demand for antibiotics and antivirals. Agrochemical innovations, especially eco-friendly pesticides, boost usage as a synthesis intermediate.

Emerging markets in MEA and Latin America present untapped potential amid agricultural growth. Greener synthesis technologies attract investments, reducing phosgene dependency.

Strategic partnerships between chemical producers and pharma firms accelerate market penetration. Digital supply chain tools enhance efficiency, opening doors for mid-tier players.

- Bio-based alternatives integration for sustainable production.

- Expansion into peptide therapeutics for oncology drugs.

- R&D in flow chemistry to improve yields and safety.

Market Challenges

Regulatory hurdles pose major barriers, with stringent REACH and EPA rules on toxic emissions. Handling risks from corrosiveness demand costly safety infrastructure.

Supply chain disruptions from raw material volatility, like ethanol prices, impact margins. Environmental concerns over phosgene byproduct push for alternatives, raising R&D costs.

Competition from substitutes like dimethyl carbonate in esterification challenges dominance. Geopolitical tensions in Asia affect export reliability.

Market Demand

Pharmaceutical manufacturing drives 50% of demand, focusing on carbamate-based drugs. Agrochemicals claim 30%, used in herbicide intermediates. Remaining demand spans dyes, polymers, and fine chemicals.

Asia-Pacific demand surges at 5.1% CAGR, outpacing global averages. Industrialization in India fuels agro needs, while China’s pharma boom sustains volumes.

Post-pandemic recovery amplifies API production, elevating chloroformate needs. Custom synthesis services for niche APIs further stimulate uptake.

Market Trends

Sustainability trends favor low-emission production processes. Biocatalytic methods gain traction, minimizing hazardous reagents.

Digitalization via AI-optimized reactions enhances efficiency. Continuous flow manufacturing reduces waste, aligning with green chemistry.

Regional shifts see APAC dominance solidify, with MEA emerging via agrotech investments. Patent surges in efficient synthesis signal innovation waves.

- Rise of peptide drugs boosting high-purity demand.

- Customization for specialty chemicals.

- Blockchain for traceability in pharma supply chains.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com